스포트라이트

Craftsman, Model Builder, Model Maker, Product Development Carpenter, Sample Builder, Sample Maker, Sample Worker, Scale Model Maker, Design Prototype Specialist, Prototype Fabricator

When we think of models, we might picture the small model cars or trains that hobbyists like to assemble. But models serve important functions in several industries such as architecture, automotive engineering, and industrial manufacturing!

In manufacturing, for instance, before a product is ready to be mass-produced and sent to stores, it’s got to be tested out. Part of that process is to build prototypes and mock-ups to demonstrate that the product’s design works in real life. The models are then rigorously checked for quality assurance and consumer friendliness before being approved for production.

These detailed product models are carefully crafted by Model Makers to give stakeholders and testers something they can see, touch, and try for themselves. The models are crucial for providing “proof of concept” – and for revealing any underlying problems that may require finetuning or redesign.

Working closely with designers and engineers, Model Makers ensure their finished models accurately represent the intended design and function within the requested parameters. They use hand tools and operate a wide array of machines to create precision parts out of materials like wood, plastics, and metals. They also incorporate other components, such as internal electronic devices, as needed.

Although it’s a relatively small career field, Model Makers are crucial players in the manufacturing industry. Without their hard work and diligence, we wouldn’t have half the products we use and rely on every day!

- Bringing ideas to life through physical models

- Contributing to product development and innovation

- Opportunities to work with advanced manufacturing technologies

- Collaborating with creative and technical professionals

근무 일정

- Model Makers typically work full-time in workshops, manufacturing facilities, or design studios. Their schedules may have to flex to accommodate deadlines and production cycles.

일반적인 업무

- Examine drawings, blueprints, and technical specifications for proposed models

- Collaborate with engineers and designers to adjust designs, as needed

- Use CAD and CAM software to modify design elements

- Determine dimensions for necessary materials to build models

- Determine the necessary equipment and plan out the sequence of operations

- Program CNC machines to fabricate model parts, or collaborate with CNC machinists or operators

- 블레이드, 고정 장치 등과 같은 기계 구성품을 조정합니다.

- Determine which blank types to use to create a workpiece. Verify the tolerance of materials to be machined

- Operate machines such as lathes, saws, presses, etc. to create parts or molds

- Mark guidelines and reference points on materials. Use patterns or other references, as needed

- Use hand tools, files, grinders, sanders, hammers, dies, molds, jigs, and other tools, as needed to shape and smooth workpieces to the required dimensions

- Use power tools to insert holes in parts

- Align and join parts using bolts and screws, or via welding or gluing

- Insert mechanical, electrical, and electronic components into models, ensuring proper wiring and soldering

- 품목에 결함이 있는지 검사합니다. 필요에 따라 기계를 조정합니다.

- 측정기를 사용하여 최종 제작품의 치수를 확인합니다. 완성된 제품이 요구 사항을 준수하는지 확인합니다.

- Test prototypes for proper functioning

- Rework parts as necessary to ensure they meet standards

- Present models to stakeholders for feedback and approval

추가 책임

- Keep track of all details such as materials used, final dimensions of parts, production processes, etc. to ensure standardization for future work

- Maintain and repair tools and equipment

- 필수 개인 보호 장비를 착용하고 정해진 안전 프로토콜을 준수하세요.

- 기술 매뉴얼 및 신기술에 대한 최신 정보

- 기술 문서 및 데이터 스프레드시트 유지 관리

- Train and supervise junior model makers and apprentices

- Participate in product development meetings

- 안전 및 환경 규정 준수 보장

소프트 스킬

- 알림

- 분석

- 디테일에 대한 관심

- 커뮤니케이션 기술

- 규정 준수 지향

- 창의성

- 비판적 사고

- 규율

- 독립

- 관찰

- 조직

- 인내심

- 계획

- 문제 해결

- 체력

- 팀워크

- 시간 관리

기술 능력

- Computer-aided manufacturing software like Autodesk Fusion 360, SOLIDWORKS, Solid Edge, Siemens NX CAM, GibbsCAM, Mastercam, etc.

- Computer-aided design programs like Autodesk AutoCAD, CATIA, PTC Creo Parametric, and SolidCAM

- Computer numerical control (CNC) machining

- 3D printing programs

- Knowledge of various materials and their properties

- Hand tool proficiency

- 블루프린트 읽기

- Basic electronics

- Welding and soldering

- 제조 기업

- 디자인 회사

- 건축 회사

- Film and entertainment studios

- Prototype development firms

- 교육 기관

Model Makers are expected to produce highly accurate, detailed models within allotted timeframes. This requires expertise, precision, and often long hours to meet project deadlines.

The work can be physically demanding, requiring fine motor skills and attention to safety protocols. But the satisfaction of turning a concept into a tangible, functioning product can be very rewarding!

3D printing and CAD software have revolutionized model making, enabling more intricate models while reducing production time and costs. There’s also an industry shift towards replacing traditional materials with biodegradable or recyclable alternatives. In addition, companies are turning more to eco-friendly processes that reduce waste and energy consumption.

Another trend is the integration of augmented and virtual reality, allowing designers to project digital models into real-world environments or become immersed in a 3D space for real-time interaction. To some extent, these new technologies are actually reducing the need for physical model-making, but they’re also making it much easier to collaborate on projects remotely.

Model Makers are very hands-on people who might have enjoyed creating things from a young age. They likely spent hours on hobbies such as model building, woodworking, or crafting. Many grew up with a natural curiosity about how things are made!

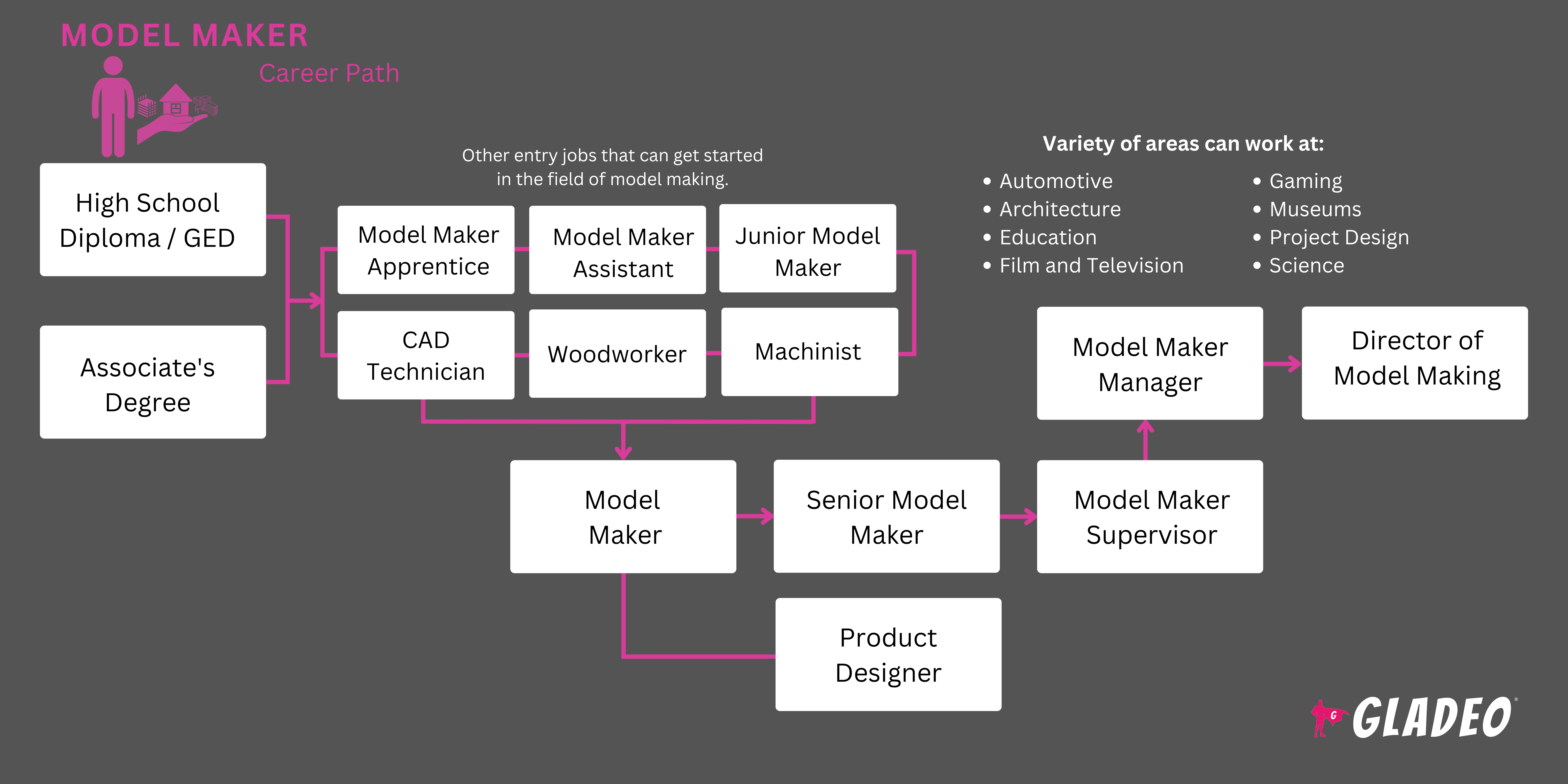

- The educational requirements to become a Model Maker aren’t set in stone

- Some get started with a bit of vocational training or a certificate. Others may pursue an associate degree or even a bachelor’s degree in industrial design, manufacturing technology, or a related field

- Common course subjects include:

- 3D printing

- 블루프린트 읽기

- CAM 프로그래밍 및 G-코드

- CNC machining

- 컴퓨터 지원 설계

- 치수 측정

- Manufacturing processes

- Material science

- 수학(미적분, 삼각함수, 선형대수, 기하학, 통계)

- Mechanical drafting

- 밀링 애플리케이션 및 프로그래밍

- Prototyping techniques

- 상점 안전

- 용접 및 금속 접합

- Many Model Makers learn through practical experience via internships, apprenticeships, or related jobs

- Students can learn a lot from online courses such as Autodesk’s 19-hour Intro to CAD, CAM, and Practical CNC Machining offered via Coursera. There’s also a four-month Autodesk CAD/CAM for Manufacturing Specialization which includes a hands-on project!

- Familiarity with augmented reality (AR) and virtual reality (VR) tools can enhance a Model Maker’s capabilities and career prospects

- Model Makers don’t usually need a four-year degree but often take classes related to CAD, CNC machining, industrial design, manufacturing technology, or related fields.

- Look for programs with well-equipped, modernized workshops where you can get practical hands-on experience and learn about the latest technologies.

- Programs should have seasoned faculty members and, ideally, opportunities for internships or cooperative learning with local employers.

- Consider the cost of tuition, discounts, and local scholarship opportunities (in addition to federal aid).

- Think about your schedule and flexibility when deciding whether to enroll in an on-campus, online, or hybrid program. Some courses may be better done in person to get hands-on experience.

- Also consider programs that can train you on using AR and VR tools in relation to model making!

- Sign up for plenty of math (arithmetic, algebra, geometry, and trigonometry), physics, computer science, materials science, design, art, and shop classes in high school

- 기계 도면 및 청사진 읽기 학습 고려

- Enroll in a community college or vocational/technical school program to learn about CAD, CAM, CNC machining, 3D printing, welding, virtual reality, and other related topics

- You can also take online courses from Coursera, Udemy, edX, Pluralsight, LinkedIn Learning, etc.

- 가공 또는 매장 업무와 관련된 아르바이트를 통해 실제 경험을 쌓으세요.

- 이력서 작성을 시작하고 업무 경험을 배우고 쌓으면서 이력서에 추가하세요.

- 채용 공고를 미리 검토하여 평균 요구 사항을 확인하세요.

- Request to do an informational interview with a working Model Maker

- 향후 구직 참고자료가 될 수 있는 연락처 목록(이메일 주소 또는 전화번호 포함)을 작성하세요.

- Study books, online articles, and video tutorials related to model-making

- Join online forums to ask questions and learn from experienced professionals

- Engage with clubs and groups to learn, share, make friends, and grow your network

- Build a portfolio of projects to showcase your skills

- Check out job portals such as Indeed, Simply Hired, Glassdoor, and Craigslist

- 지원하기 전에 최대한 많은 실제 매장 업무 경험을 쌓으세요.

- Consider enlisting in the military in a machinist career field. You’ll get free paid training and can earn job experience that can be used in a civilian career, too

- Seek out apprenticeships sponsored by employers, unions, or trade associations

- Ask a working Model Maker for job-seeking tips

- 자격증이나 준학사 학위 취득을 고려해 보세요. 학력은 경쟁에서 돋보이는 데 도움이 될 수 있습니다.

- 학교 커리어 센터에 채용 담당자 및 취업 박람회와의 연결에 대한 도움을 요청하세요.

- 잠재적 추천인에게 추천을 해줄지, 추천서를 써줄지 미리 물어보세요.

- Check out online Model Maker resume templates and review potential job interview questions

- Before going into an interview, brush up on the latest news about the field. Be ready to discuss your insights about relevant trends and changes

- 제조업체 및 소프트웨어 가이드를 공부하세요. 사용하는 프로그램과 기계에 대한 전문가 되기

- Ask your supervisor how you can improve your CAD, CAM, and CNC machine knowledge and skills to better serve the company

- Knock out specialized certifications related to cutting-edge technologies like AR and VR

- Demonstrate that you can work independently and collaborate effectively on teams

- Train new workers patiently and thoroughly. Make sure to always wear appropriate personal protective equipment to avoid mishaps and hazards

- Write “how-to” articles to establish yourself as an industry leader

- Branch out into different types of model-making to expand your horizons

- Consider relocating if needed to advance your career!

웹 사이트

- 3Ds Max

- 미국 건축가 협회

- 미국 금형 제작자 협회

- 제조 기술 협회

- 에너지 엔지니어 협회

- Association of Professional Model Makers

- AutoCAD

- Autodesk Fusion 360

- 오토데스크 인벤터

- 블렌더

- CATIA

- Fabricators and Manufacturers Association

- G2.com

- GrabCAD

- IMAGINEiT

- 미국 산업 디자이너 협회

- 국제 기계공 및 항공우주 근로자 협회

- 국제 기계 윤활 협의회

- 국제 유체 동력 학회

- 국제 노동 조합, 미국 자동차, 항공 우주 및 농업 기구 노동자 연합

- Make:

- Manufacturing.gov

- 제조 연구소

- 국립 금속 가공 기술 연구소

- 전국 툴링 및 머시닝 협회

- NX - 유니그래픽

- 정밀 가공 제품 협회

- 정밀 금속 성형 협회

- Revit

- Shapeways

- SketchUp

- 제조 엔지니어 협회

- 솔리드 엣지

- SOLIDWORKS

- TCT Magazine

- TITANS of CNC Machining

- 유나이티드 스틸웍스

- Unity 3D

도서

- Making Things Move DIY Mechanisms for Inventors, Hobbyists, and Artists, by Dustyn Roberts

- Prototyping: A Practitioner’s Guide, by Todd Zaki Warfel

- Rapid Prototyping: Principles and Applications, by Chua Chee Kai and Leong Kah Fai

Model Makers are key players in the manufacturing industry. But the career field is relatively small, and may not be suitable for everyone, so check out our list of related occupations below for additional career ideas!

- Architectural Drafter

- CAD 기술자

- CNC Programmer

- 전기 및 전자 장비 조립업체

- Engine Assembler

- 산업 디자이너

- 산업 기계 정비사

- Machinist

- 제조 엔지니어

- 기계 엔지니어

- Patternmaker

- 제품 디자이너

- Prototype Technician

- Set and Exhibit Designer

- Structural Metal Fabricator

- 도구 및 다이 메이커

뉴스피드

주요 채용 정보

온라인 강좌 및 도구

연봉 기대치

New workers start around $46K. Median pay is $67K per year. Highly experienced workers can earn around $91K.